First of all, even though we talk about “urethane” when referring to fingerboard wheels, the correct term is “polyurethane” (abbreviated to PU).

Choosing your (poly)urethane means first choosing a polyurethane that works for the use you intend to make of it.

The PU used for full-size skateboard wheels and fingerboard wheels is not exactly the same. This is why a fingerboard wheel machined from a skateboard wheel will not have the same properties as a fingerboard wheel.

This article will only discuss cast polyurethane resins.

Hardness

Fingerboard wheels generally have a hardness between 60 and 100 Shore D (60D - 100D). The most common hardnesses are 65D, 70D, and 75D. It is important to understand how the Shore hardness scales work, and above all to know that there are two hardness scales:

- Shore A => For soft materials (e.g., molding silicone)

- Shore D => For hard materials (which is what we are interested in)

Shore A vs Shore D equivalents

Generally, a polyurethane resin graded in Shore A will not have the right properties for fingerboard manufacturing, as it is too soft, lacks integrity, and marks very easily (according to my tests, even at 100A!).

A wheel with a hardness of 60D to 75D will tend to grip a little, while a wheel with a hardness greater than 80D is considered “hard” and a little more slippery.

Degassing or compressing resin?

Degassing resin

Degassing resin involves removing bubbles from the resin before pouring it into the mold. It is good to know that you can degas it before mixing parts A & B, but it is also possible after mixing, you just have to be quick! To degas effectively, you need a high-performance vacuum chamber. Food vacuum chambers work, but they take a very long time, from 15 minutes to over an hour. We don't have that kind of time with many resins because of how quickly they harden.

Compressing your resin

Compressing a resin makes the bubbles in the mixture invisible. The bubbles are still present but are (almost) invisible. This is a proven technique that is much simpler (and less expensive) than a vacuum chamber, but a little more risky if you don't do it right. Too much pressure in an unsuitable tank and you'll end up with a “pipe bomb” in your living room 💣💥

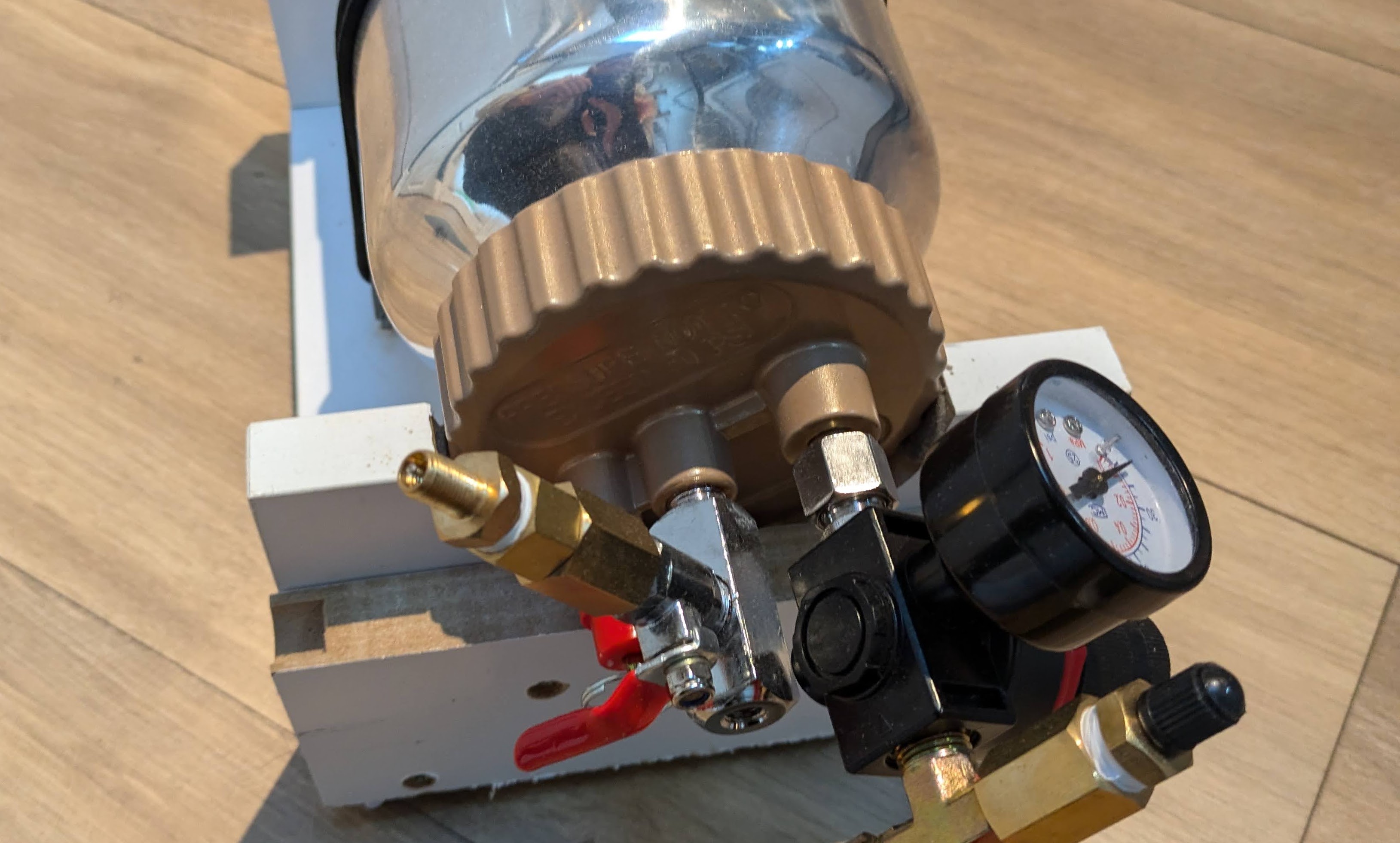

It is possible to make your own compression tank with a pressure tank, a bicycle pump, and a few connectors! I made my own tank with a Vevor 2L paint tank, et un adaptateur valve de vélo (and a few additional connectors)

DIY Pressure chamber

DIY Pressure chamber

Working time & drying time

For working time, if you plan to make several sets of wheels at the same time, choose a resin with a longer working time.

As for drying time, if it is long (1 hour or more), this allows more time for bubbles to form and moisture to penetrate the resin, weakening the final product once dry.

Drying time has a significant impact on the final result of the wheels, so it is sometimes necessary to test several resins to achieve the desired result. Even if this is (very) expensive.